Frequently Asked Questions

Q: What is an edge bevel?

A: The edge bevel (also called secondary bevel), is the grind that forms the cutting edge. It comes down from the primary blade grind to the apex of the edge.

Q: what do different grits mean, and how are they different?

A: Grit size indicates how large the abrasive material in a whetstone is. You might be most familiar with grits in terms of sandpaper; whetstones are the same idea. Generally speaking, low/coarse grits are anything below 500, medium grits are 500-1,500, and high grits are above 1,500. A lower grit will result in a toothier, rougher edge. Often, this will be good for cutting through softer materials, like rope, webbing, or soft produce. A higher grit edge is more polished and refined, better for harder materials like wood or thick plastics. This edge, especially when taken to a mirror finish, will also look nicer.

A finish below 1,000 grit will have a very visible scratch pattern and no polish. Finishes around 1,000 will have a barely visible scratch pattern and some polish. And finishes above 2,000 will be highly refined up to mirror polished. For freehand edges, I offer 500, 1,000, 2,500, and mirror polish finishes. For Edge Pro edges, I offer 500, 700, 1,000, 4,000, and mirror polish finishes.

In general, a lower grit edge will work better for higher (obtuse) angles, and a more polished edge will be better for lower (acute) angles.

Q: What do sharpening angles mean?

A: The angle that you sharpen at will change how a blade cuts. A higher angle (more obtuse) creates a more robust edge but will reduce the slicing performance. A lower angle (more acute) creates a keener cutting edge but is less robust. For a hard-use outdoor or work knife, a higher angle will generally be better. Conversely, for a lighter used knife or kitchen knife, a lower angle will offer better performance. In general, a high angle is 18-25 degrees, and a low angle is 12-18 degrees.

NOTE: When I talk about angles, I exclusively use the per-side angle! The inclusive edge angle will be the per-side angle doubled. For example, when I reference a 15 degree edge bevel, that refers to the angle on each side of the bevel; so the inclusive measurement would be 30 degrees.

For most folding knives, I would recommend something between 15 and 20 degrees (depending on how the blade is ground). For larger outdoor knives, an angle between 18 and 23 degrees will make a good, robust edge. Kitchen knives can usually get away with lower angles of 10 to 15 degrees or even lower, depending on how they are used. I am always happy to discuss all of these details and decide what will work best for you. Please note: I sharpen freehand on whetstones, so there will naturally be some variation in angles, but the edge will approximate any chosen angle.

Q: What is freehand sharpening?

A: Freehand sharpening is used (primarily) with whetstones (or diamond stones, sandpaper on leather, etc.) set on a table, counter, or over a sink. This method does not use any clamps or angle guides, so it relies on the sharpener to maintain a consistent angle. Freehand edges will have a natural micro-convexity. Note, I cannot achieve exact angles sharpening freehand, but I can get close to your desired angle. For a super precise edge, I recommend an Edge Pro edge.

Q: What is a fixed/guided-angle system?

A: Fixed/guided-angle systems utilize a platform or clamp that secures the blade in place. An arm holds the whetstone at a fixed angle as it is drawn along the edge. This system allows the sharpener to maintain a very precise angle along the entire edge and will create an extremely flat, even bevel. See my services page for pricing info on an Edge Pro edge. The price is higher because it takes more time and effort, but you will get a more precise result; I can also achieve exact bevel angles with this system.

Q: Why do I sharpen freehand with whetstones?

A: For most knives, I use freehand sharpening because it allows greater speed and flexibility than something like a fixed-angle system. This is especially relevant for longer (or thinner) blades, like kitchen knives or larger fixed blades. Many guided-angle systems struggle with these types of knives. I do offer a precision edge using the Edge Pro system, though, but this is only available for shorter blades. manual sharpening takes more time and skill, but I believe the process is well worth it.

Sharpening by hand (especially freehand) is a connection to the tradition of using and caring for knives, an essential human tool throughout history. It’s an artisan craft, and it brings me joy to keep this tradition alive in my work.

I DO NOT use any powered equipment for standard knife sharpening! This is why my prices are higher than many other sharpening services; if you want something sharpened right, it takes more time and effort. The only time a belt sander comes into my process is for a handle or blade reshaping (or possibly a serious tip repair, where a substantial blade reshaping is required). I will also use a belt sander to set the edges on axes and machetes.

Most lower-cost sharpening “professionals” will use belt grinders or other powered equipment to speed up their process. This often results in uneven edges, unintentional recurves, rounded tips, and massive amounts of material removed unnecessarily. Grinder edges are also almost inevitably overheated, which reduces edge retention and toughness by up to 40%. With whetstones, I can carefully and slowly remove only as much material as I need to. This takes more work and time, but it will result in better edges and more life out of your blade.

Q: What is a micro bevel?

A: A micro bevel is a small additional bevel on the edge bevel applied at a slightly higher angle at the end of sharpening. The advantages in this are increased toughness, but more importantly easier maintenance. Because a micro bevel creates a very small bevel on the apex of the edge, it can be very easily touched up to keep your knife sharp. With a micro bevel, you only have a very thin section of steel to remove as you touch up the edge, making it quick and easy. If you are newer to maintaining an edge or need some extra toughness, then a micro bevel might be a good decision.

Q: what is a convex edge? How is it different from a regular edge bevel?

A: A convex edge is a rounded edge bevel, versus a regular flat bevel (also called V-grind). Convex edges will tend to be slightly tougher and are especially good for woodcarving, whittling, or bushcraft applications.

In freehand sharpening, there is a very slight natural convexity, so you already get some of those benefits of a convex edge, just more minimally. When doing a convex edge, I exaggerate that convexity and blend it with the primary blade grind so the edge transitions smoothly to the blade grind. I can do a convex edge upon request.

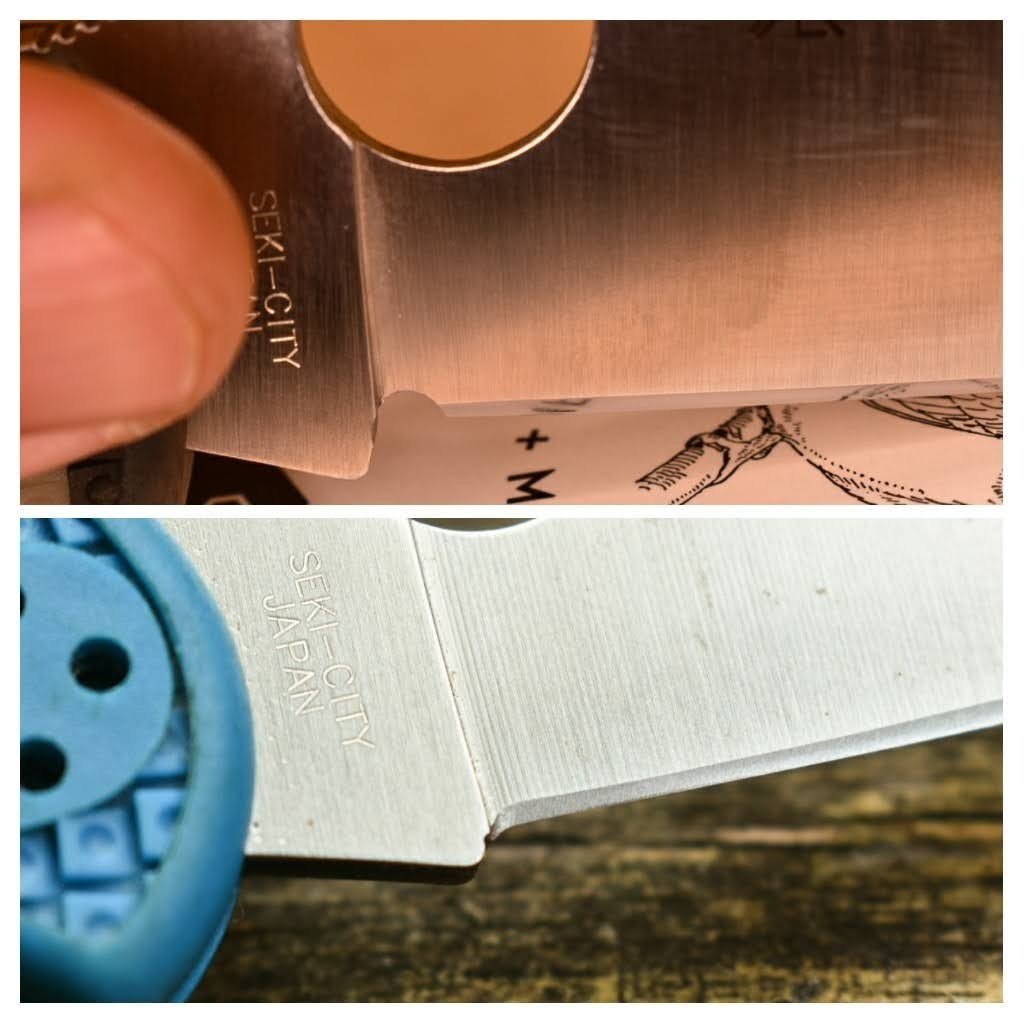

Q: What is a sharpening choil?

A: A sharpening choil is a small notch at the heel of the blade. This notch allows the even sharpening of the edge along its entire length. If there is not a sharpening choil, or if the choil is too small, you’ll run into one of three possibilities. First, the portion of the edge near the heel of the blade won’t actually get sharp. Second, the edge bevel will get substantially wider at the heel than along the rest of the edge. Third, the edge will start to recurve directly in front of the heel. See the “Modifications” section of my gallery for some pictures to illustrate this better. Also

Q: What is my sharpening process?

A: First I will assess the edge. Here, I will check the tip to see if it needs any repair, look for any chips or damage, and look at the consistency of the current edge bevel (is it the same width down the length of the blade? Is it consistent from side to side?). This assessment will determine what grit I need to start with. For a badly damaged edge, or one that needs some heavy reprofiling, I will start with a very coarse stone, either 120, 220, or 320 grit. If the bevel looks reasonably consistent and the edge is not too damaged, then I’ll start at 500 grit. With these initial stones, I set the new edge bevel, making it consistent and removing any damage. Then I’ll move on to the next grit stone in my progression to remove the scratches from the first stone and make sure everything looks good and consistent. A common progression for me is 320, 500, 1,000, then 2,500 grit. Whatever stone I finish on, I’ll make long, even strokes, to make sure the scratch pattern is consistent along the entire edge. After the edge is perfect, I do a series of light passes to remove any burr on the edge.

After the stones, I strop on leather to remove any leftover micro-burr and refine the apex of the edge; usually, this will be 1 micron, but it’s dependent on what finish the customer requested. For a mirror edge, the strop progression will normally be 4 micron, 1 micron, 0.5 micron, and sometimes 0.125 micron. Before stropping, I will carefully clean off any slurry or debris on the blade, and the same between each strop.